23.02.2024 | Eicklingen/Niedersachsen

Source One Plastics commissions sorting and recycling plant for plastic waste

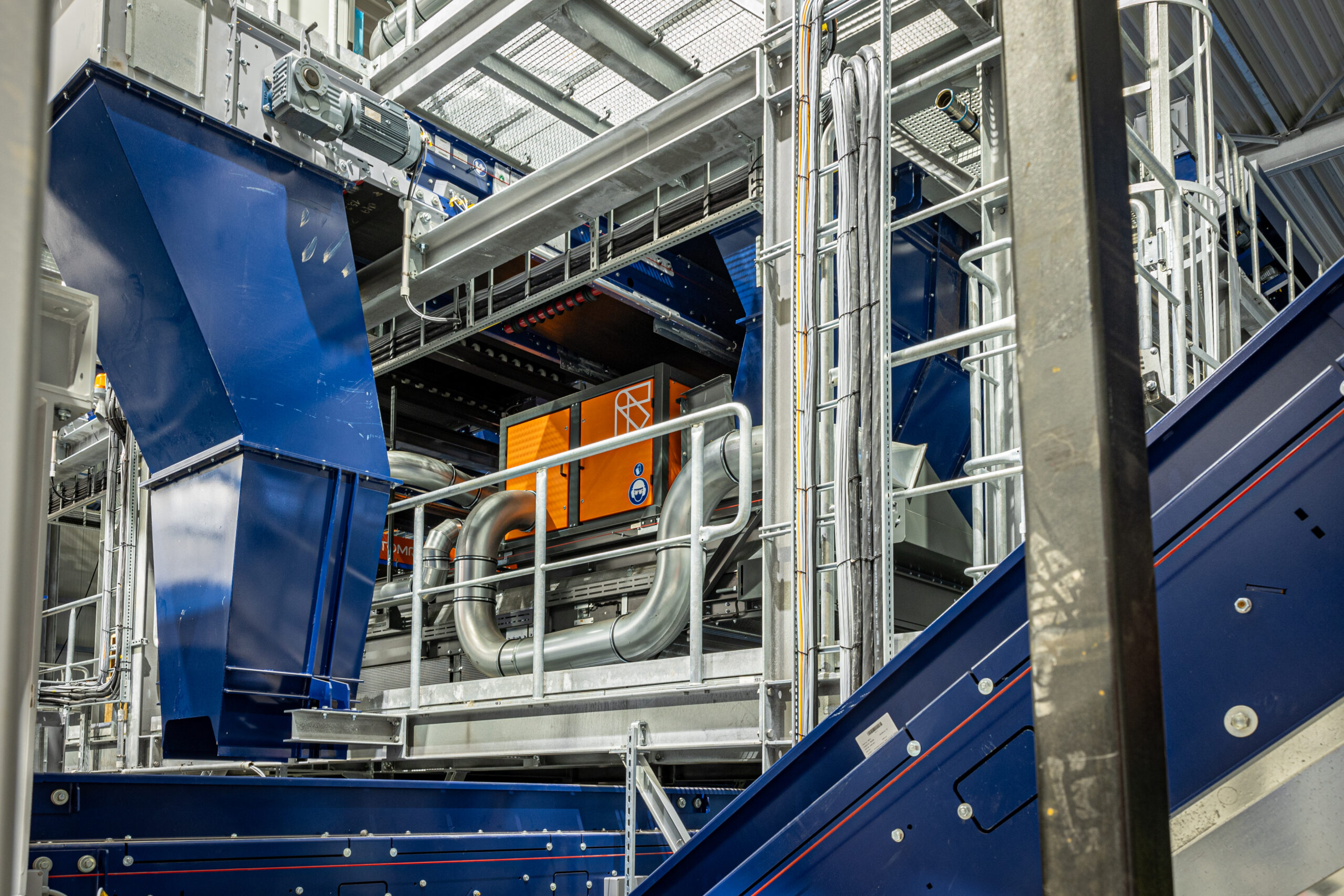

Eicklingen/Lower Saxony. Source One Plastics GmbH, a joint venture between 23 Oaks Investments and LyondellBasell, has successfully commissioned its plant for sorting and recycling plastic waste in Eicklingen successfully into operation. The innovative plant processes difficult-to-recycle plastic waste plastic waste such as mixed plastic packaging and flexible polyolefins, which would otherwise usually be incinerated. otherwise usually sent for incineration. The expected annual processing capacity of 70,000 tons corresponds to the amount of plastic waste produced by more than 1.5 million German citizens per year. citizens produce per year.

The plant uses an innovative drying process that reduces energy consumption by up to conventional plastic recycling technologies by up to thirty percent. The system is designed designed to minimize the occurrence of fine plastic dust and its release into the environment. is minimized. The plant is powered by locally generated renewable energy. The plastic waste processed in Eicklingen The plastic waste processed in Eicklingen will form a significant part of the input material for the first advanced recycling plant that LyondellBasell is building at the Wesseling site in Germany. site in Germany.

"We celebrate the opening of our Source One Plastics joint venture facility today with valued partners, employees and local stakeholders. partners, employees and local stakeholders,” says Yvonne van der Laan, LyondellBasell Executive Vice President, Circular and Low Carbon Solutions. “This is another important milestone in our strategy to transform recycled material into high-quality polymers. This state-of-the-art, advanced sorting facility will convert mixed plastic waste from the end-user sector into raw material and process it at our integrated site in Cologne. There we will use state-of-the-art technologies to close the loop on plastics and create sustainable solutions for society. create sustainable solutions for society.”

The Source One Plastics joint venture will offer a broad portfolio of services, including Sourcing, sorting and pre-treatment of plastic waste for advanced recycling. With process, LyondellBasell produces high-quality plastics for a range of applications.

As a strategic solutions provider for the sustainable use of plastics, 23 Oaks combines global experience and extensive knowledge in all areas of the circular economy. “We combine this expertise “We combine this expertise with a distinctive operational approach,” says Kai Hoyer, owner of 23 Oaks Investments. “With the Source One Plastics plant, we are today inaugurating another ecologically and economically economically attractive solution for the upcycling of PCR plastic waste. We are proud of this, to see our idea of a better circular economy in action. With the help of AI technology our system will recognize and sort material compositions with product precision. This gives us the the prerequisites for true closed loops, the supreme discipline of the circular economy.”